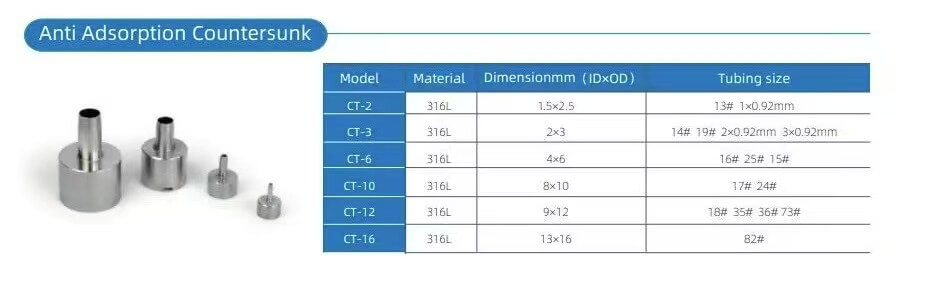

Anti-Floating Countersunk:

Engineered for reliability in critical fluid applications, our anti-floating countersunk components feature a patented non-stick surface design that eliminates component displacement or floating caused by fluid buoyancy. Ideal for lab, pharmaceutical, and industrial settings, this innovation ensures stable operation, precision, and long-term performance.

1. Non-Stick Surface for Secure Positioning

- Anti-Floating Technology: The specially treated countersunk surface reduces adhesion and repels fluid buoyancy, keeping components firmly in place during high-flow or multi-head operations.

- No Unexpected Movement: Eliminates risks of misalignment or detachment, ensuring consistent performance in repetitive filling, dispensing, or mixing tasks.

2. Laminar Flow Design for Precision

- Controlled Fluid Dynamics: Laminar flow-compatible components minimize turbulence, enabling uniform fluid distribution.

- Ideal for Sensitive Applications: Perfect for biopharmaceutical fluids, food-grade materials, or high-viscosity adhesives that require zero contamination or measurement errors.

3. Heavy-Duty 316L Stainless Steel Construction

- Corrosion & Wear Resistance: Built with medical-grade 316L stainless steel, these countersunks withstand harsh chemicals (e.g., sulfuric acid, hydrofluoric acid) and high-frequency use.

- Long Lifespan: Outlasts standard countersunks by 3X, reducing replacement costs and downtime in industrial environments.

4. FDA-Compliant & Biocompatible

- Regulatory Ready: Meets strict FDA guidelines for food contact and biocompatibility standards, ensuring safety for pharmaceutical, medical device, and food processing applications.

- Hygienic Design: Smooth surfaces and zero crevices simplify cleaning—ideal for sterile environments.

5. Tool-Free Installation & Versatile Compatibility

- Plug-and-Play Integration: Fits most fluid handling systems (peristaltic pumps, microfluidic devices, dispensers) via standard threaded, snap, or flange connections—no custom modifications needed.

- Adjustable for Any Setup: Height and spacing flexibility adapts, supporting diverse workflow requirements.

6. Low-Residue Design for Efficiency

- Minimal Liquid Trapping: Streamlined channels and anti-adsorption properties reduce residue by 90%, cutting cleaning time and improving material utilization.

- Faster Process Switches: Spend less time on maintenance and more on production—perfect for high-throughput environments.