When selecting motors for industrial, medical, or laboratory equipment, a common question arises: “What’s the lifespan difference between DC motors, stepper motors, and peristaltic pump motors? How do I choose the right one?”

In this guide, we break down motor lifespan data, key selection criteria, and real-world tips to optimize performance and cost-effectiveness.

Motor Lifespan Comparison

| Motor Type | Typical Lifespan | Key Influencing Factors |

|---|---|---|

| DC Motors | 300–1,000 hours | Brush wear (for brushed types), load cycles, cooling efficiency |

| Stepper Motors | 8,000–20,000+ hours | Heat management, driver quality, operating torque |

| Peristaltic Pumps | 3,000–15,000 hours* | Motor type + tubing wear (primary lifespan limiter) |

*Note: Peristaltic pump lifespan depends on both the motor (stepper/DC) and tubing replacement cycles

How to Choose the Right Motor

1. For Short-Term, Low-Precision Tasks: DC Motors

Best For: Intermittent operations, budget-friendly projects (e.g., cooling fans, simple conveyors).

Pros: Low cost, simple speed control.

Cons: Shorter lifespan, not ideal for continuous or high-precision use.

2. For High-Precision, Long-Duration Work: Stepper Motors

Best For: Applications requiring precise positioning and durability (e.g., 3D printers, medical dosing systems).

Pros: Accurate open-loop control, longer lifespan.

Cons: Higher initial cost, requires heat management.

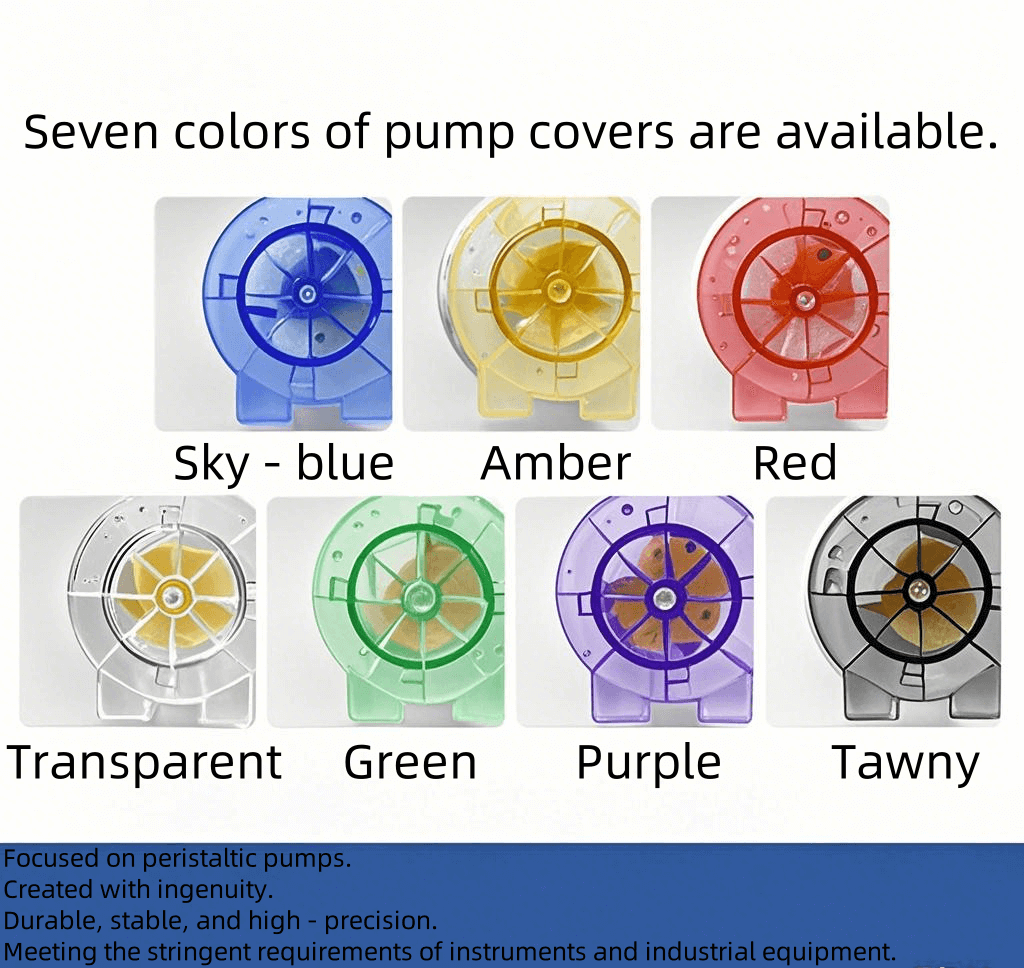

3. For Fluid Handling with Low Shear: Peristaltic Pumps

Best For: Biopharma, labs, or industries transferring sensitive fluids (e.g., cell cultures, corrosive chemicals).

Pros: Contamination-free operation, easy tubing replacement.

Cons: Lifespan tied to tubing maintenance.

Choosing between DC motors, stepper motors, and peristaltic pumps hinges on lifespan needs, precision requirements, and operating conditions. For high-precision, long-term reliability, stepper motors lead the pack. For cost-sensitive, intermittent tasks, DC motors suffice. Always pair peristaltic pumps with quality tubing for optimal performance.

Need Help? Contact TODA Fluid Control for custom motor solutions tailored to your industry!