When building a reliable piping system, every detail counts—especially the fittings. From water purifiers to medical equipment, choosing the right plastic PP fittings, Luer connectors, or check valves ensures your system runs smoothly without leaks or contamination. Here’s a practical guide to picking the perfect fittings for your project, whether it’s for industrial, medical, or food-related applications.

Why Material Matters for Long-Lasting Performance

The foundation of any fitting is its material, and polypropylene (PP) stands out for good reason:

Resilient and Corrosion-Free: PP withstands high temperatures and resists chemical corrosion, making it a durable choice for tough environments.

Safe for Food and Water: Food-grade PP fittings are non-toxic and odorless, ensuring no harmful substances contaminate water, beverages, or food ingredients. They’re a must for water purifiers and food processing systems.

Broad Applications: From laboratories to medical devices and environmental setups, PP’s versatility makes it a go-to material for reliable performance.

Selecting high-quality PP fittings guarantees safety and durability, no matter the application.

Choosing the Right Fitting Type for Your System

Different systems demand different fittings. Picking the right type can streamline your setup and prevent costly errors. Here’s what you need to know:

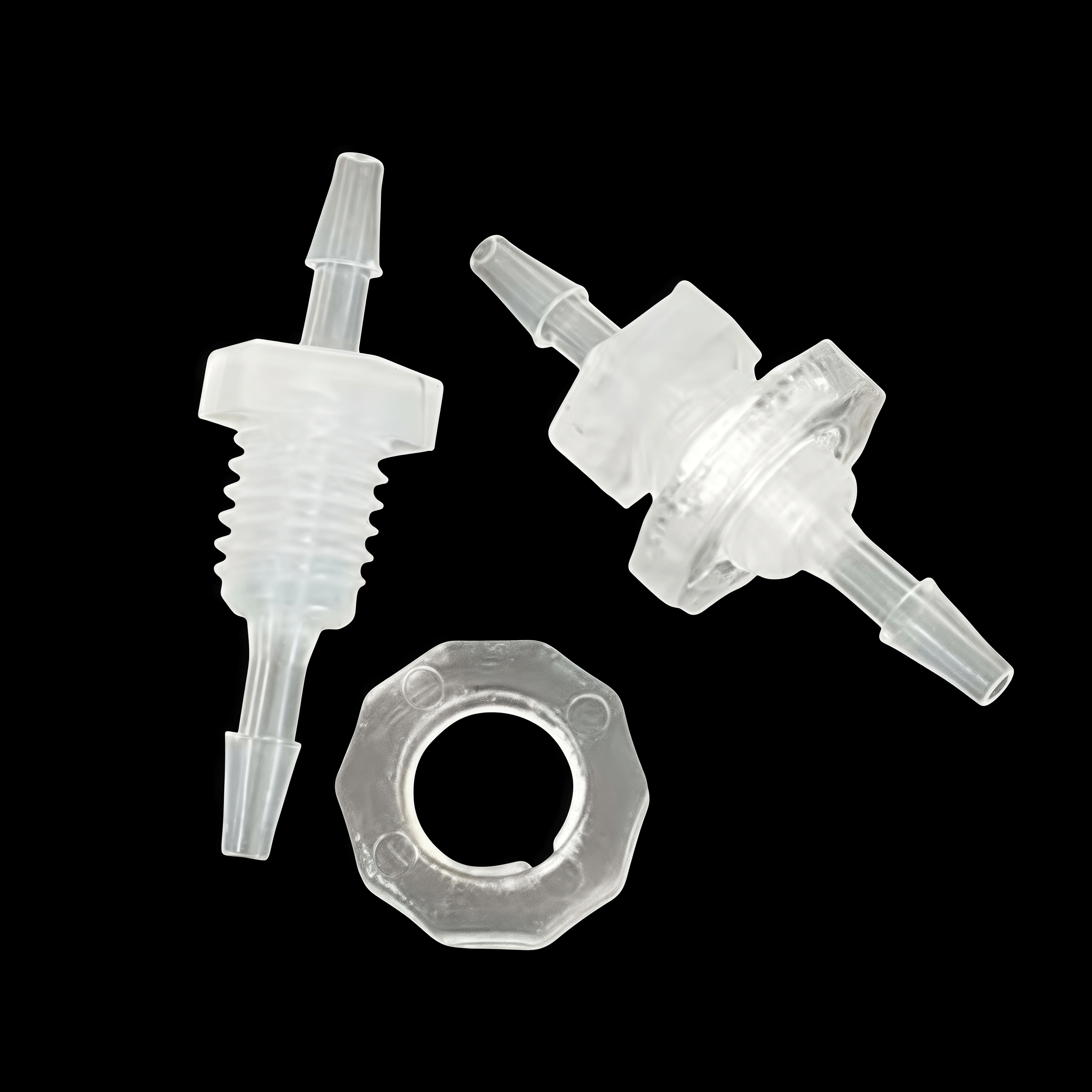

Luer Connectors: With their standardized tapered design, Luer connectors are perfect for precision applications like medical tubing or lab equipment. They ensure a tight, leak-proof seal and are easy to connect or disconnect.

Panel-Mount Fittings: These fittings secure directly to equipment panels, eliminating the need for extra supports and keeping your piping layout clean and efficient.

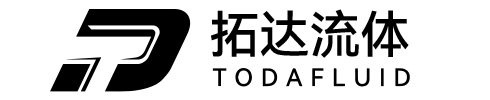

Check Valves: Designed to allow one-way fluid flow, check valves prevent backflow, protecting systems like water dispensers or hydraulic setups from contamination.

Matching the fitting type to your system’s needs is key to efficiency and reliability.

Size It Right to Avoid Leaks

A fitting’s size can make or break your system. A perfect fit ensures a secure, leak-free connection:

Barb Fittings: The barbed design must align precisely with your hose’s inner diameter. Even a small mismatch can cause leaks or disconnections.

Double-Check Dimensions: Always verify the hose diameter and fitting specs before purchasing to avoid issues down the line.

Getting the size right upfront saves time, money, and frustration.

Small Components, Big Results

Don’t underestimate the power of a well-chosen fitting. The right plastic PP fittings, Luer connectors, or check valves can prevent leaks, protect against contamination, and keep your system running flawlessly. Whether you’re working on a water purifier, medical device, or industrial project, quality fittings are the key to success.

Ready to find the perfect fittings? Check out our selection of PP fittings, Luer connectors, and check valves to build a system you can trust.