The Root Cause: Inner Diameter Variation in Extruded Tubing

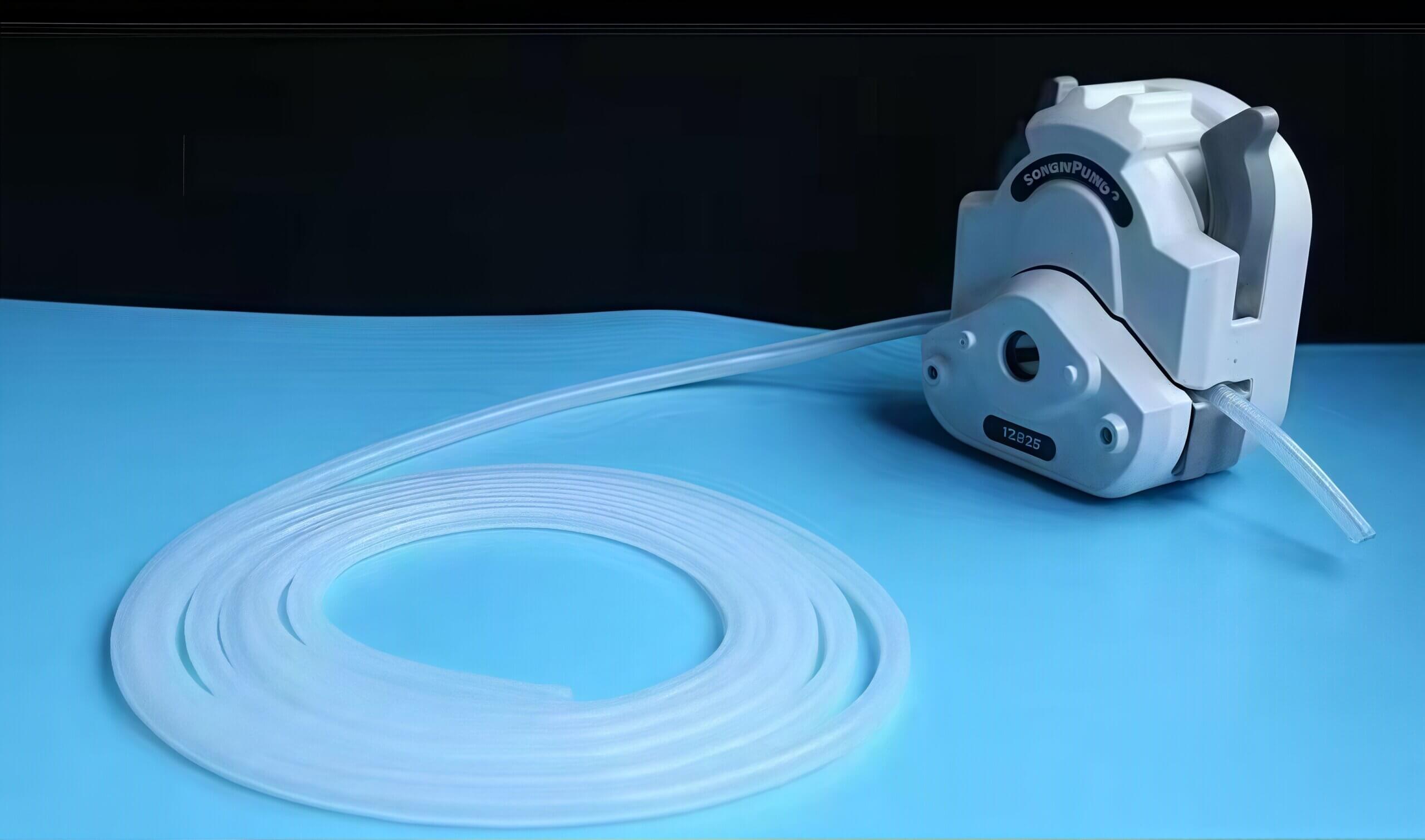

In multi-channel peristaltic pump applications, ensuring highly consistent flow rates across all channels is critical for precise fluid handling (e.g., filling, dispensing, reagent addition). However, a common challenge is flow rate variation between channels. The primary source of this error is often not the pump head itself, but the tubing that conveys the fluid.

Why is tubing the culprit? It’s fundamentally linked to its manufacturing process. Peristaltic pump tubing is typically produced using an extrusion process, unlike many rigid plastic parts that are injection molded.

The Nature of Extrusion: During extrusion, molten elastomer material is forced through a die to form the tube. In this process, human control factors and environmental fluctuations (like temperature, pressure, pulling speed) inevitably lead to slight variations in the tubing’s inner diameter (ID).

Variation Within a Single Tube: Surprisingly, this variation isn’t just present between different batches of tubing (which is usually obvious), but can even occur at different points along the same continuous length of extruded tubing. While the variation within a single tube is typically less pronounced than batch-to-batch differences, it remains significant enough to impact high-precision applications.

In a multi-channel pump, if the tubing used in each channel has different IDs (whether from batch differences or different positions on the same reel), the actual output flow rate of each channel will differ, even if the pump head speed is identical. This is the fundamental cause of flow rate error.

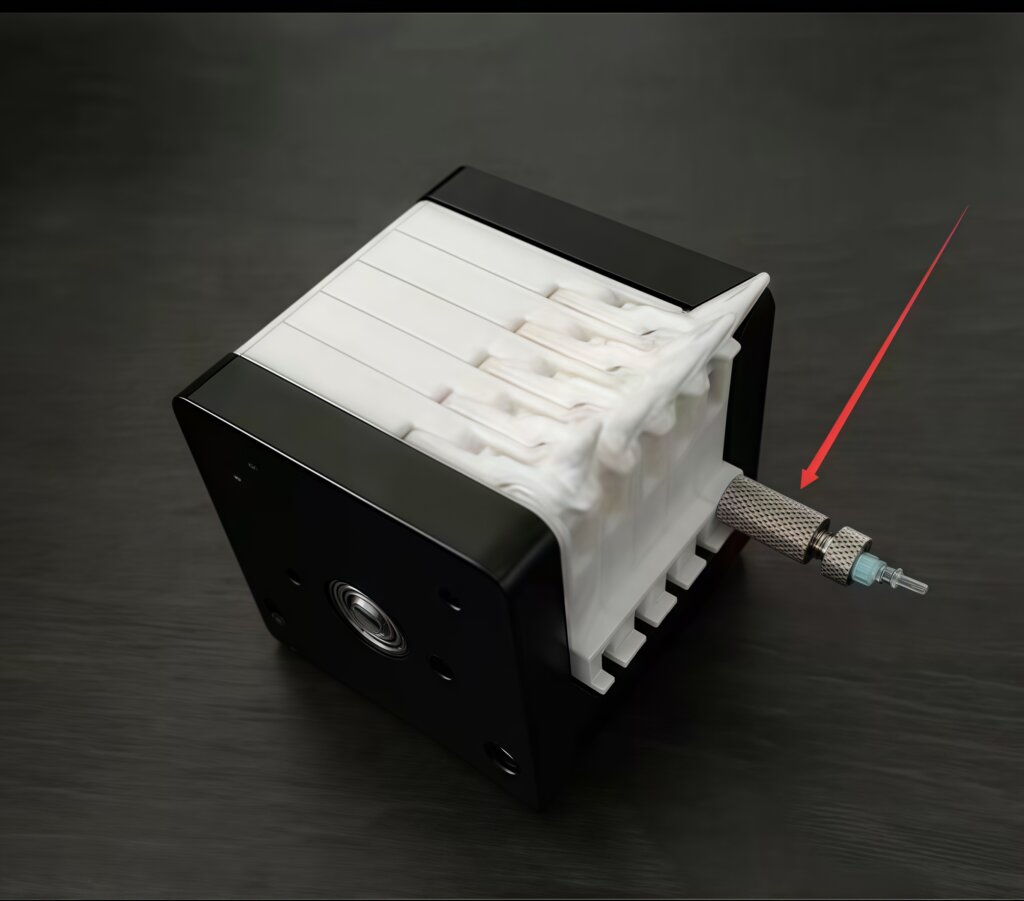

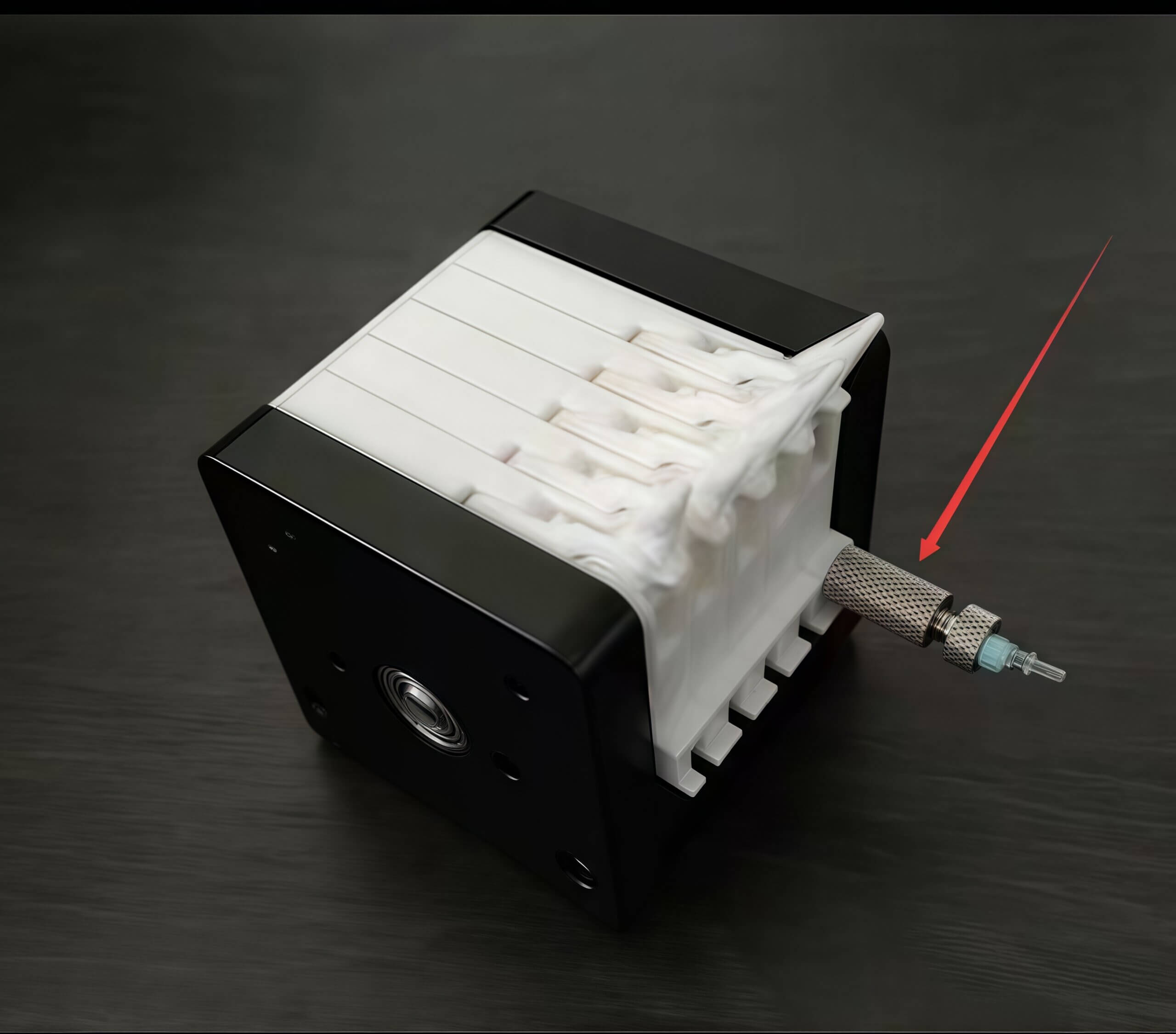

Our Solution: Channel Fine-Tuning Mechanisms

To overcome the challenge posed by the inherent variation in extruded tubing ID and ensure highly consistent multi-channel flow rates, we employ a key design feature: precise fine-tuning mechanisms integrated beside each channel on the pump head.

Dramatically Improved Multi-Channel Consistency: Directly compensates for the primary source of error (tubing ID variation).

Easy Operation: Quick and efficient setup without constantly changing tubing batches or spending excessive time finding perfectly matched sections.

Ensures End-Application Accuracy: Critical for applications like filling, bioreactor feeding, or precise chemical addition where strict channel-to-channel consistency is required.

Maximizes Tubing Utilization: Reduces the need for tubing with extremely tight tolerances, improving tubing utilization.

Want to see how our fine-tuning mechanism works in action? Contact our technical team or request a demo video to learn more about how we help customers achieve optimal performance in fluid dispensing systems.